The cold deformation process (Swaging) and the mechanical stress relief process (Stress Relief) are of great importance in the tube ends cold deformation lines. The internal stress relief process takes place through induction furnaces which rise the temperature of tube ends up to 700°C.

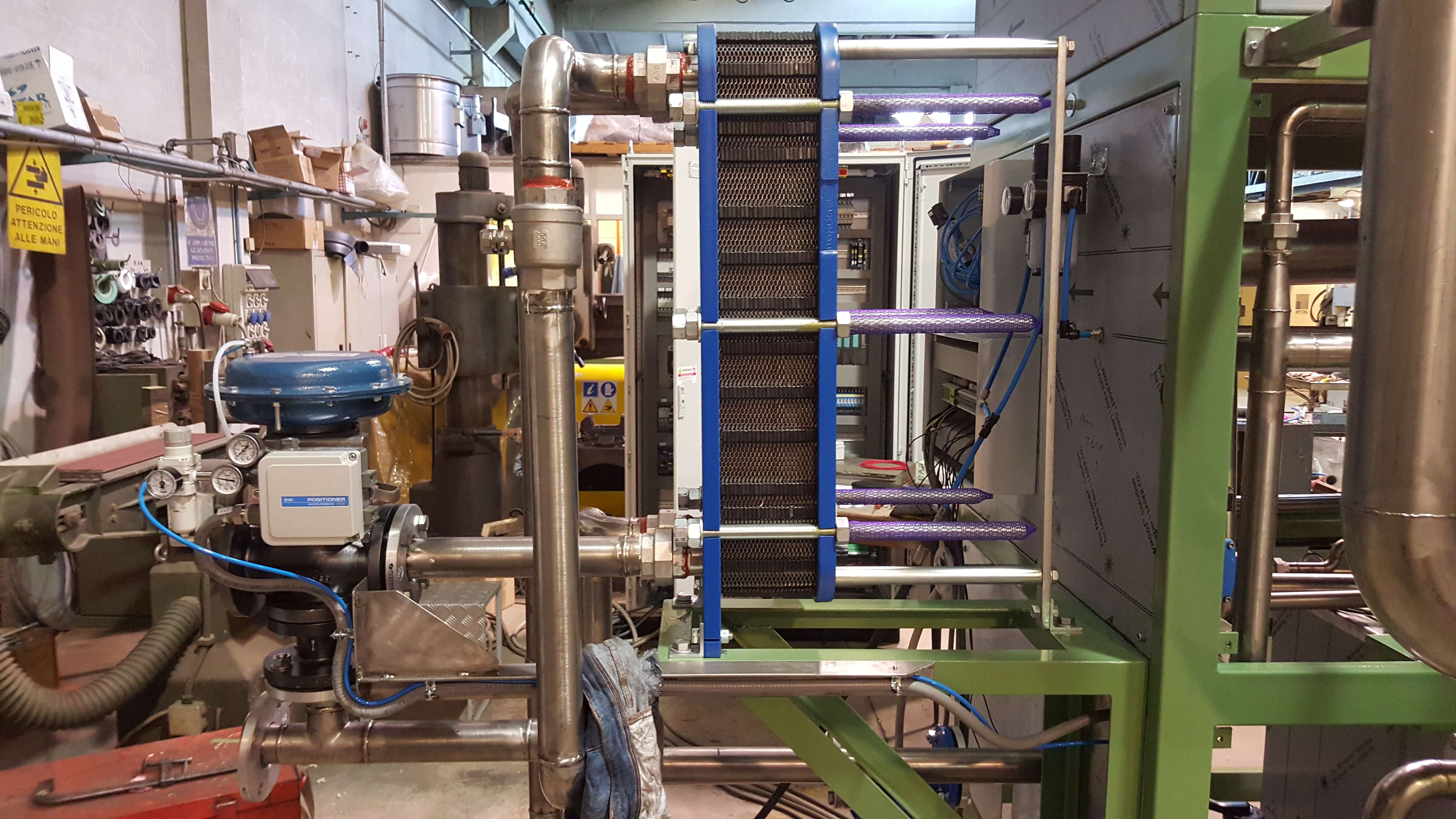

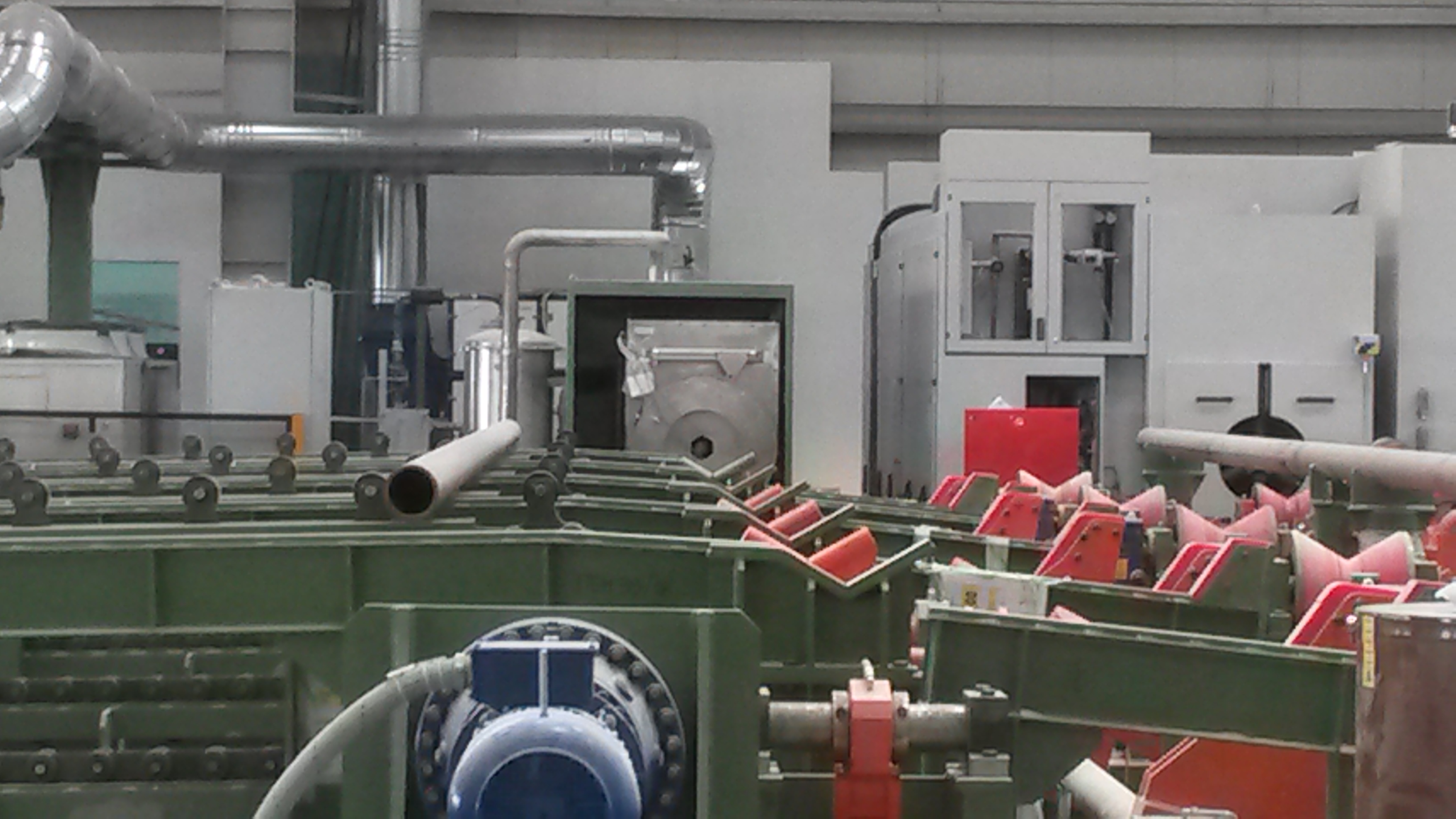

Before starting with the next mechanical processing the tube temperature must drop to 60°C. To speed up the cooling process and to reduce the length of the line achieving the same production capability TECNOLOGIE INDUSTRIALI offers water-cooling machines which enable a temperature dropping (from 350°C to 60°C) in less than 90 seconds. Water-cooling machines features:

- The water-cooling machines are available both in compact solution (with integrated cooling-water preparation tank) and in integrated solution (with separated cooling-water preparation tank shared among different cooling heads)

- Electronic level control system for automatic water refilling

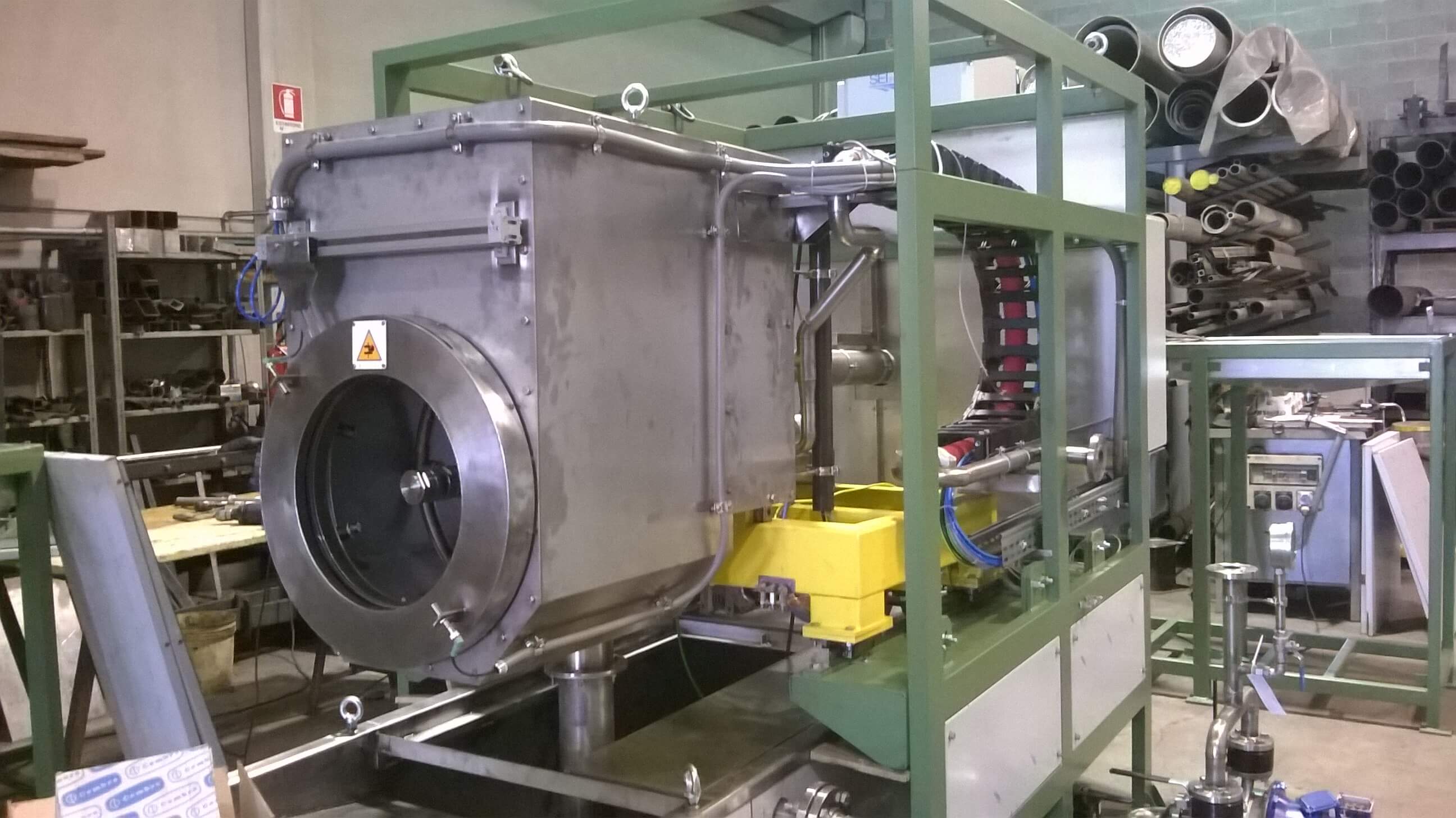

- Adjustable cooling head for self-centering of different tube diameters

- Control working system of cooling head for different treatments length

- Washing system selector for internal tube washing (PIN) and/or external tube washing (BOX)

- Self-adapting cooling head closure to different tube diameter to reduce cooling solution leak from the treated area

- Condensate recovery system for fumes caused by contact of cooling solution with hot tube surfaces. The system is connected to a central fume suction plant or placed directly on the machine

- Electrical system and management software (stand-alone or integrated to the management system line)

All water-cooling machines are designed and manufactured according to specific custom needs.

+39 0363 800066

+39 0363 800066