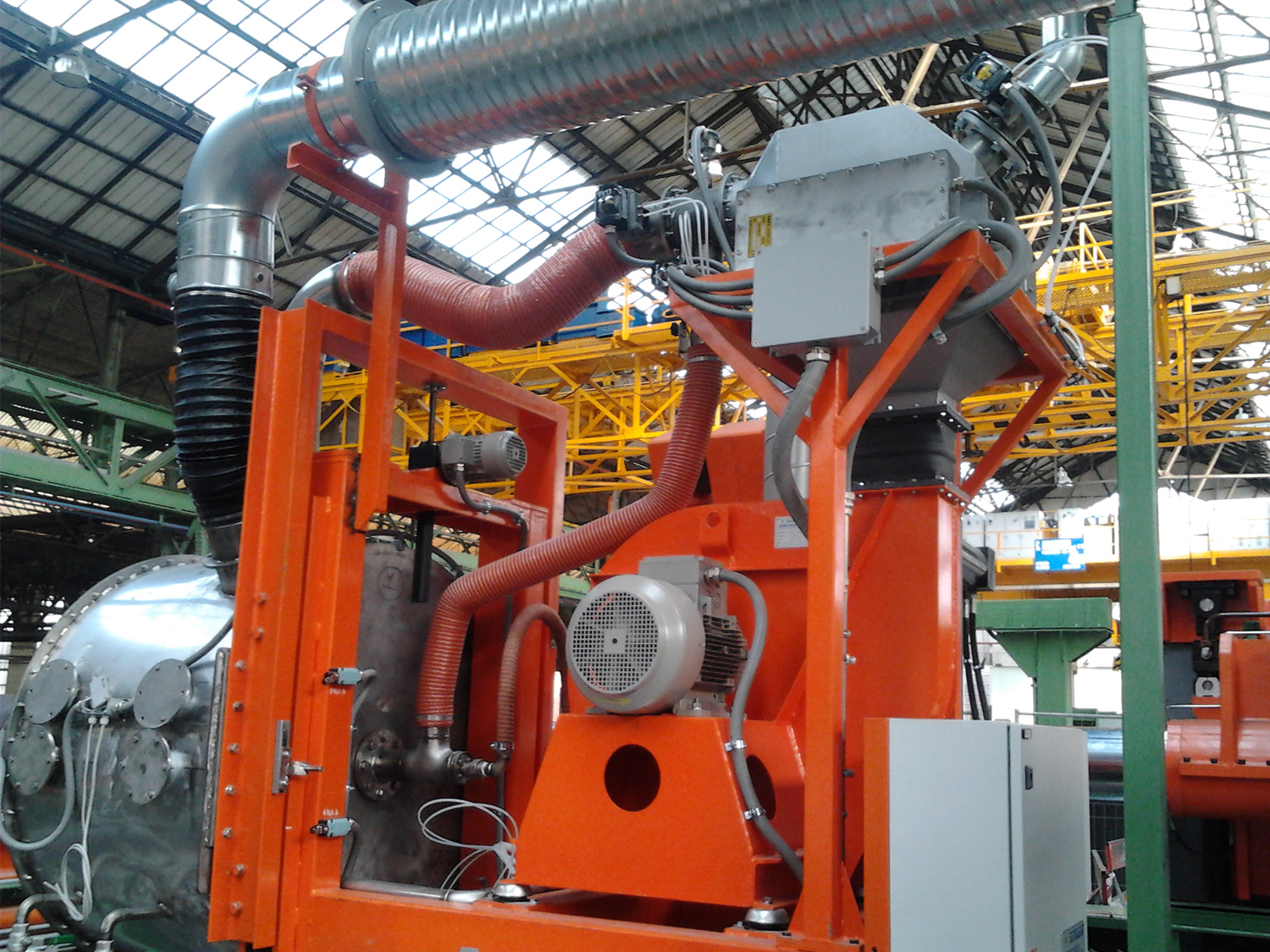

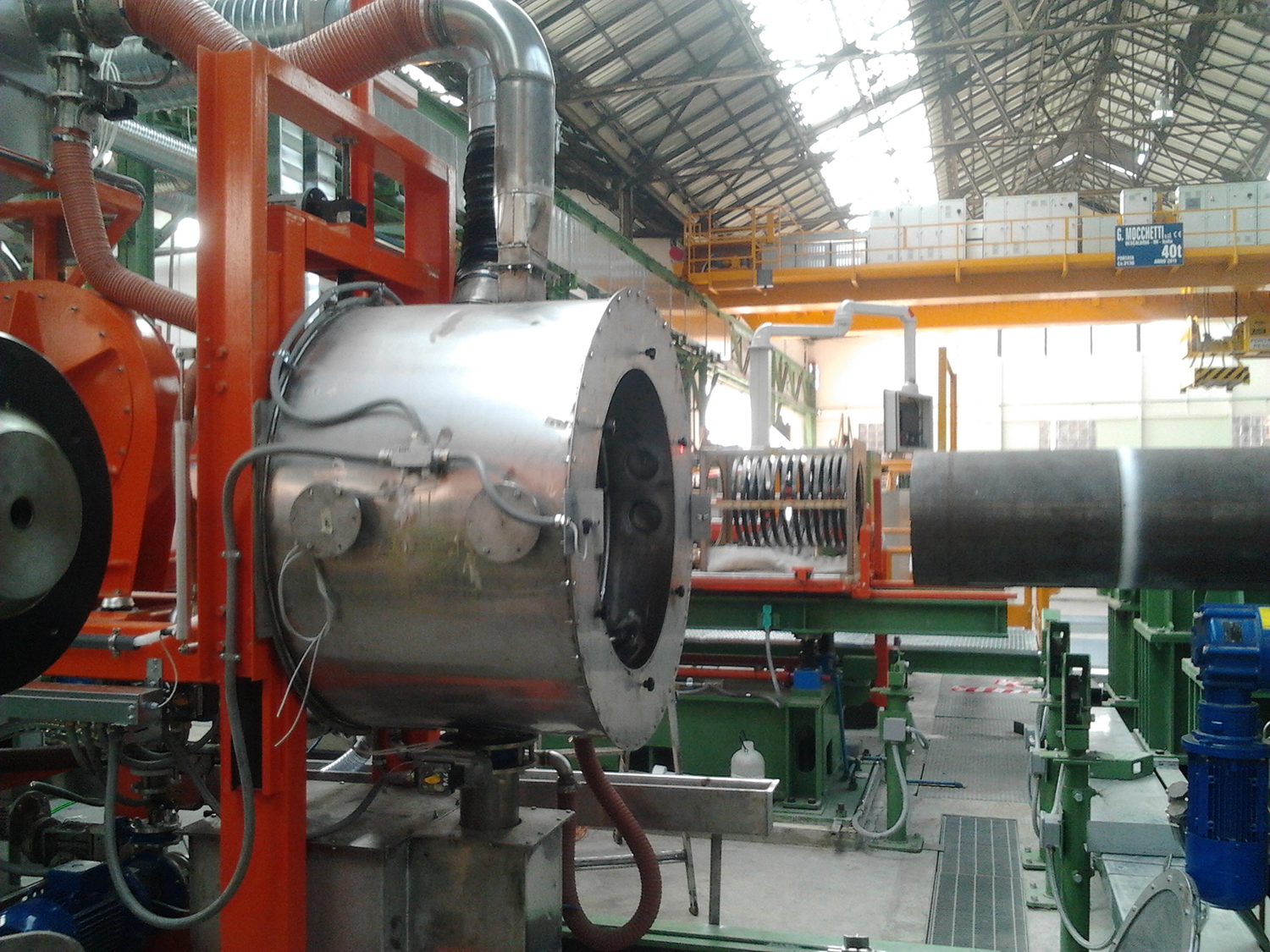

After a Swaging operation (cold deformation of the tube end), or before a finishing operation (sandblasting to facilitate the painting operations), it’s necessary to place a machine to remove all traces of grease and/or oil from the internal (PIN) and external (BOX) surface of the tube end. TECNOLOGIE INDUSTRIALI provides specific degreasing machines to be placed in the thread and painting lines of the tubes. The main features of these degreasing machines are:

- Compact machine with integrated tank for the preparation of the degreasing solution;

- Dual-filtration system, gravity filter and oil skimmer, to remove the impurity coming from the tube surface from the degreasing solution permitting an extended use of the degreasing solution;

- Automatic water refilling through an electronic level control;

- Automatic degreasing solution refilling linking its consumption to production data;/li>

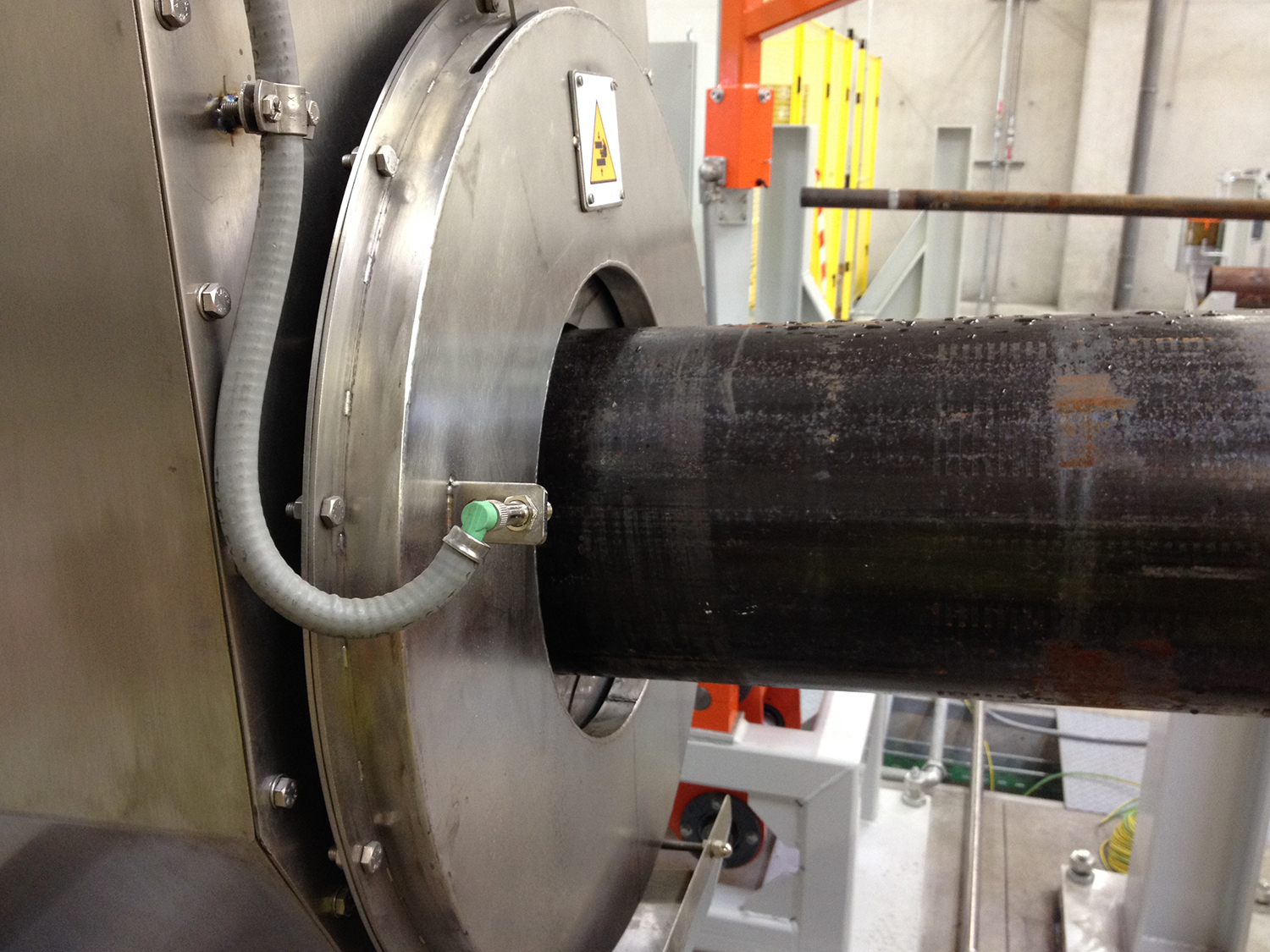

- Height adjustable degreasing head; self-centering on tube diameters;

- Controlled feed of the washing head according to the desired length of the treated area;

- Option for internal tube washing (PIN) and/or external tube washing (BOX);

- Drying system of the tube surface after degreasing operations;

- Self-adjustable degreasing head closure based on tube diameter to reduce the leakage of cooling solution from the treatment area;

- Integrated fume suction plant and no chimney needed;

- Electrical system and management software for stand-alone or in-line integrated system operation.

All the degreasing machines are designed and manufactured according to customer’s performance and dimensional requirements.

+39 0363 800066

+39 0363 800066