The phosphating coating, zinc or manganese based, is an essential process for tube production for Oil & Gas sector. The threaded ends, PIN or BOX, must first be prepared for the coating following these steps:

- Degreasing: oil – grease removal

- Rinsing: washing and removal of the previously used degreasing solution

- Activation: surface preparation before the phosphate coating (crucial in the manganese-based process

After the phosphating process the tube ends must be treated following these further steps:

- Rinsing: removal of the excess of phosphating solutions

- Passivating: fixing and protection of the phosphate coating

- Drying: protection of the coating against rust as the previous process will leave an aqueous solution on the surface

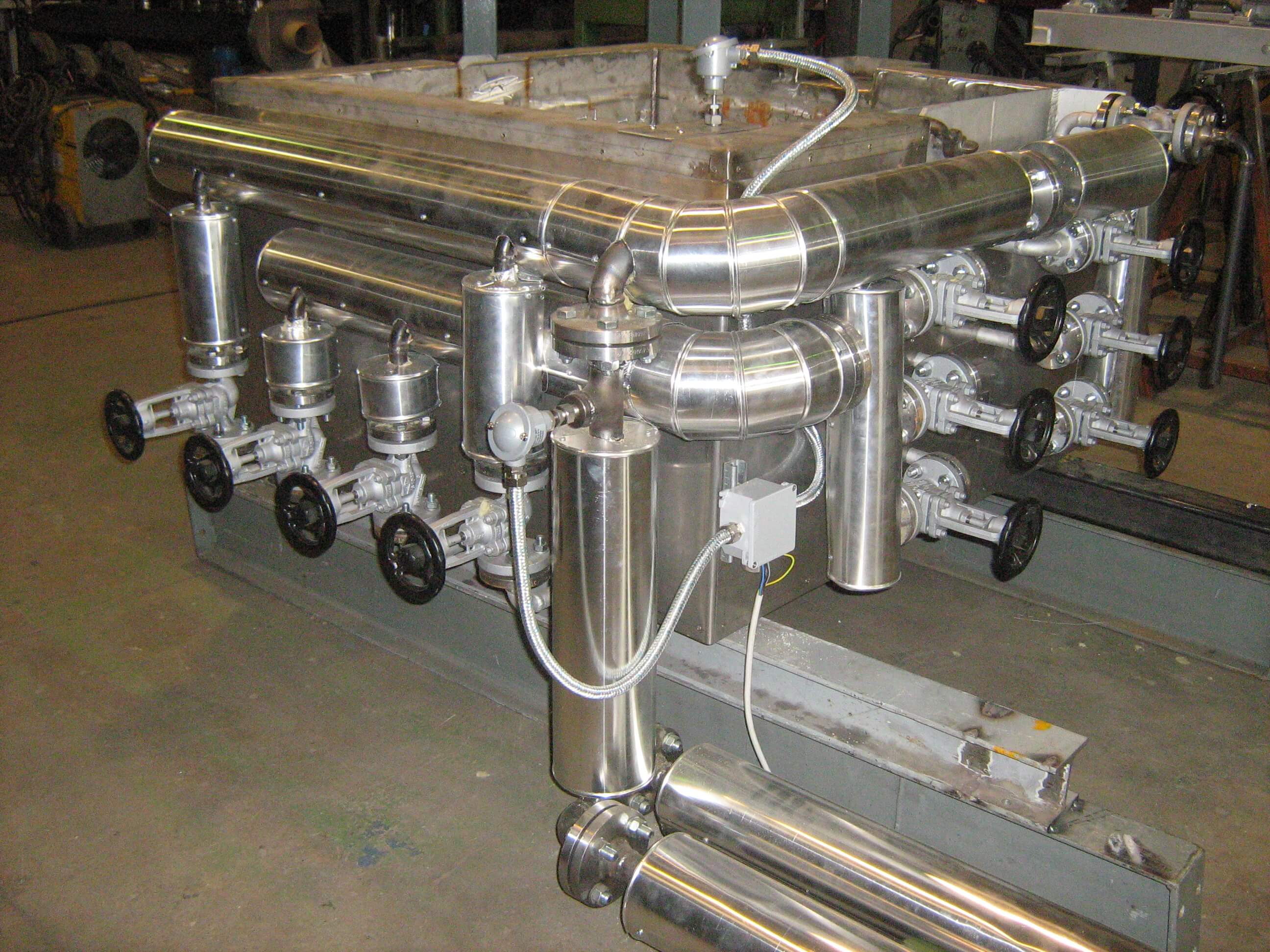

TECNOLOGIE INDUSTRIALI, thanks to its experience, designs, builds and installs tanks and phosphating plants for the zinc and manganese salts coating processes. In particular we are able to provide:

- Phosphating immersion systems

- Phosphating spray systems

- Process stations before/after phosphating process with manual or automatic operation

- Decantation and filtration systems to handle the phosphating sludge

- Diathermic oil heating systems (circulating and on site)

- Suction plant and waste air purification systems

- Tubes handling systems

All the phosphating plants are designed and built according to customers’ performance and dimensional needs.

+39 0363 800066

+39 0363 800066